Secondary Coating Line

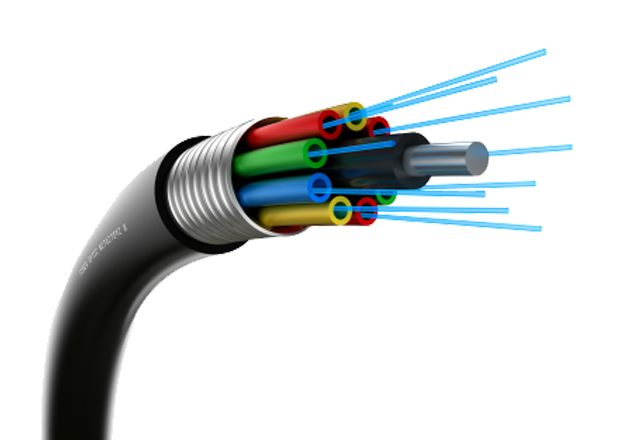

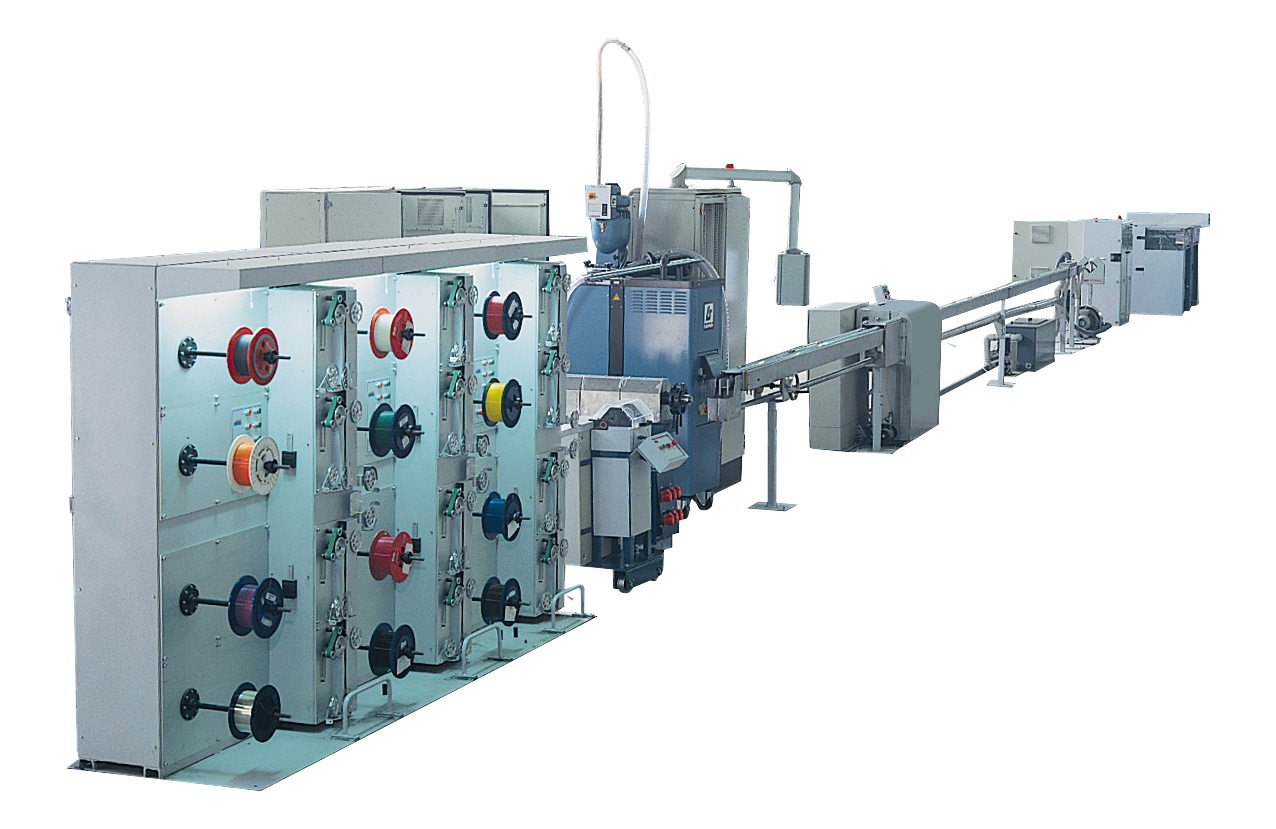

Fiber Optic Tube Lines

(Secondary Coating Line)

By making minor changes on the line configuration loose tubes, micro-tubes, tubes without gels and similar type fiber optic cables can be produced on this type of lines. Secondary Coating Lines are designed to produce single layer, double layer and with and without gelly cables.

With optional online test devices, quality of the cable is continuously analyzed and parameters are adjusted automatically; as diameter control, etc.

With the help of precision control pulling system of the line, fiber optic cables produced on the line can reach high quality with high efficiencies.

With the semi-automatic dual take-up machine, line changes reels without stopping or slowing down.

Line design between 2 to 24 fibers and final diameters between 1 mm to 4 mm.

Line speed up to 500 meters/minute.

Materials PBT and PP are used.

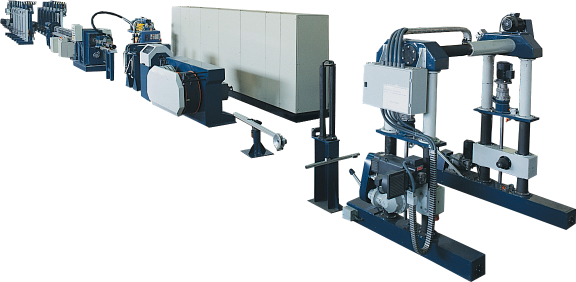

Fiber SZ Stranding Line

Fiber Optic SZ Stranding Line

Line has an elasticity of adjustable stranding capacity which enables to produce a wide range of indoor and outdoor fiber optic cable cores. Produces stranded cable cores before final sheathing

Line can produce cores with jelly or dry. According to requirements of final cable type different option units can be added to line configuration like yarn server, cross-binder, taping, etc.

Line can produce cores between 2 to 24 fibers (standard 12 fibers) with a maximum diameter of 9 mm (standard is 3,5 mm).

Cable pitches are adjustable between 80 cm to 150 cm. Line speed is 40 meter/minute with 80 cm cable pitch. Larger pitches increases line speed.